When we think of a pioneer home in the Ohio country, we invariably envision the interior being brightly lit with copious numbers of glowing candles, charmingly reflecting off surfaces of brass, copper, pewter and rustic wood burnished by hard use over time. Disappointingly, however, such romantic images exist only in the minds of artists, illustrators and perhaps greeting card designers. The reality of the situation was markedly different.

Unlike the more readily available fuel for lard, fat and grease lamps, candles made of tallow were labor-intensive to create and expensive to purchase if you weren’t crafting your own. Thus, candles, when they were available, were used very sparingly. Pioneers didn’t go lighting up their house with them like the opening of a new saloon. If they were used at all, seldom was more than one lighted at a time, and it was closely monitored to get the most life out of it, being extinguished the moment it was no longer needed.

Tallow. Tallow was made from hard animal fat, usually that of sheep or cattle. It was said that an average-sized bull yielded enough fat to produce about 26 dozen candles. Historical records show that when ships from Spain brought hides from its various colonies to shoemakers in America, they also brought to the chandlers (candle makers) the tallow from the same animals.

The chandler did not merely melt the fat, but rather “tried” (rendered) it by boiling so that the fibrous material within it would rise to the surface, where it could be skimmed off, thus increasing the purity of the resulting product.

Dipping candles

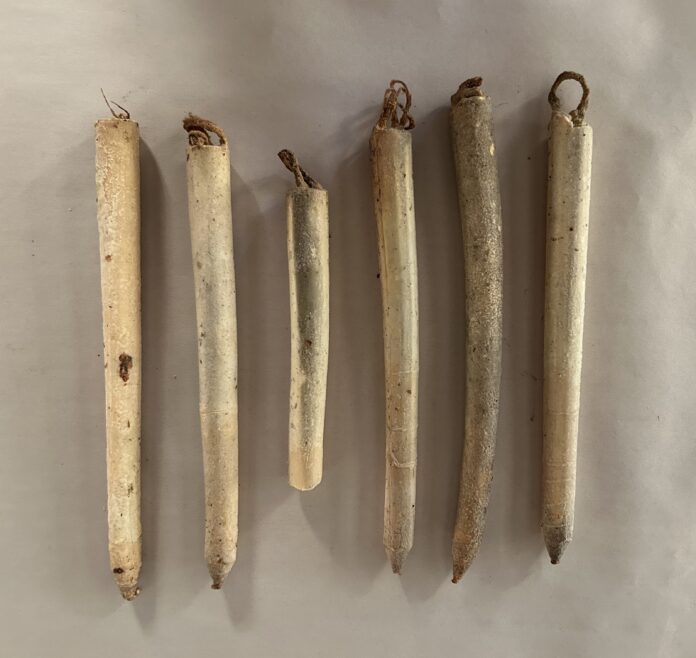

There were two completely different methods for creating candles. The first was dipping them, and the second was molding them. If the chandler was using the dipping method, he ladled the hot fat into a vessel such as an iron kettle or wooden tub, where it was allowed to cool somewhat. If the tallow was too hot, it would leave a thin deposit on the dipped cotton wick, preventing it from burning properly, or worse, it would melt off the accumulation from earlier dippings. If the tallow was too cool, it left lumpy deposits on the developing candle.

During the dipping process, the candle wicks were tied equal distances apart to wooden rods called broaches, with several broaches being tied with wicks at the same time. This allowed the chandler to dip a broach of wicks into the tallow and set it aside to cool while he took the next broach of wicks and dipped that. The chandler continued rotating through all the broaches, dipping the wicks and allowing them to cool. With each dipping, the candles grew larger in circumference until the desired size was reached. When the candles had cooled, the wicks were cut from the wooden rods, and the finished tapers were boxed away. Then the broaches were again tied with a new batch of wicks.

Candle dipping machine

An alternative to the broach method was the candle dipping machine, rarely found in complete condition today. This device had six wooden arms protruding from a central hub, which was supported by a stout shaft. At the end of each arm was suspended a wooden disc with a handle on one side. On the side opposite the handle were small iron staples to which wicks could be tied. Typically, each of these discs had about two dozen staples. The advantage of this machine was that the chandler could sit next to the tub of hot tallow, dipping the wicks attached to the disc, hanging it back on an arm, and then revolving the assembly to the next arm for dipping the next disc. By the time any given disc was completely revolved, the developing candles had dried enough to be ready for the next dipping. Through this labor-saving methodology, a gross of candles (144) could be dipped efficiently. Unfortunately, most of these candle dipping machines have had their discs separated and disbursed over the years, and antique buffs are likely to find them at markets sold in separate units.

Candle molds

The other method of crafting a candle was by pouring the hot tallow into a mold where a wick had previously been inserted. Vast numbers of candle molds were created over the years by tinsmiths, potters, pewterers and woodworkers. Tin candle molds can range in size from one to as many as 100 tubes. The most common tin candle molds have between 12 and 24 tubes. Candle molds with tubes made of pottery or pewter are typically built into a wooden framework to better support the weight. Sizes range from tiny molds for making candles that would decorate Christmas trees to exceptionally large examples for use in churches. The makers of candle molds, interestingly, often applied a level of artistry to these creations. Some examples have feet or legs of various lengths, some have unusually shaped handles, some are set in a circular configuration and some have integral containers to hold wicking and other tools.

Candle molds were set up by running the wicks through small holes in the ends of the tubes, and then tying them to thin wood or wire broaches that were laid across the top of the tubes. The hot tallow was then poured into the tubes, sometimes by using a ladle and small funnel, and sometimes utilizing a tin pan having small spouts that corresponded to the tubes of the mold. When the candles had dried, the mold was briefly immersed in warm water so that the tallow released from the tin, allowing the candles to be extracted.

Tallow candles were always put out with a hand-held snuffer, rather than being blown out. Blowing ran the risk of scattering hot tallow onto the myriad of highly flammable objects and furnishings in a pioneer home.

Because of their fragility, candles were usually carefully stored in layers with paper between them in special wooden boxes until needed.

So, was all this information … ummm … illuminating?