By 1918, automobiles had some 20 years of experimentation, as well as lots of practical use behind them and most American cars had four wheels, two for driving and the two in front steering.

By that time, virtually all had a wheel that the operator used to steer those front wheels and had settled on the left front seat for the driver.

Such standardization had not quite overtaken the volatile world of tractor design, however, and tractor design was all over the map.

Every variation of engine type and its placement, cooling systems, transmissions, wheel arrangement — in short, every component that made up a tractor was tried and touted by its manufacturer as the best, most reliable, and cheapest.

During the very early years, as farmers awakened to the advantages of internal combustion tractors and demand for the new-fangled contraptions soared, both large and small manufacturers took a fling at building tractors, along with various tinkerers, dreamers and outright crooks.

Many an unsuspecting person, believing the get-rich-quick hype of shady characters, bought stock in a phony tractor company and instead of hefty dividends, they ended up with a stack of worthless stock certificates.

Dealer networks had yet to be established, and if a farmer’s new tractor broke down, as it frequently did, his only recourse was to wire the factory to send him the offending part or, if he had no idea what was wrong, as was probable, to send a factory man to fix the thing.

Mechanics

Tractor manufacturers were often operating on a shoestring and had little money to keep a large stable of well-trained mechanics on hand. The tractor owner often sat, fuming, for several weeks before a company representative showed up.

As for tractor design, an August 1918 article in Tractor World magazine claimed there were no less than 12 different configurations of tractor wheel arrangements and six distinct crawler track arrangements. These included two driving wheels with the engine mounted between and the implement hooked to an extension behind (Moline Universal, Centaur).

Wheels

A number of different tri-cycle configurations were used: two rear driving wheels with the single front wheel in the furrow (Happy Farmer), or centered (Samson Sieve-Grip, Hart-Parr Little Devil); two front driving wheels with a centered rear one (Hackney Auto-Plow, Trenham 12-24); or two front wheels with a single driving wheel centered at the rear (Common Sense, Strite); a single rear driving furrow wheel with a nondriving rear wheel on land and a single front wheel in the furrow (Little Bull, Case 10-20); and a right-front driving wheel with a nondriving left-front wheel and a single rear wheel (Rumely All-Purpose).

A variation on the tri-cycle is found with the Gray tractor that had two front wheels with a single, wide drum driving wheel centered at the rear.

A number of different crawler tractor designs were tried as well. Early Best, Holt and Yuba crawlers had a track at each side with most of the tractor’s weight on them and a single, centered wheel out front. Steering was accomplished by turning the front wheel and using brakes or clutches on the individual tracks.

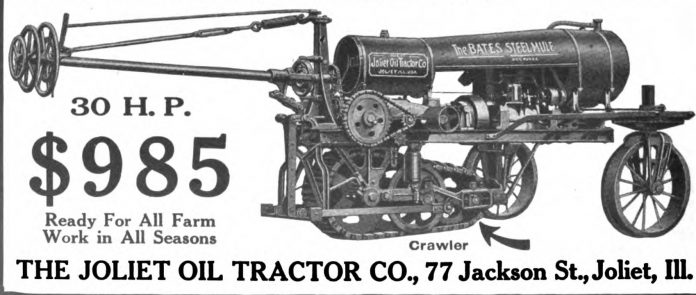

Bean Spray Pump Co. put a single crawler track up front and two steerable wheels behind, while the original Bates Steel Mule did just the opposite with a single rear track and the two wheels out front. Bates later switched to two rear tracks and two front wheels.

The Killen-Strait had the two rear tracks with a third, steerable track out front.

Engines

Early on, steering was the same as it had been in the steam traction engines, with the front axle pivoted at the center and pulled in either direction by a chain and drum system before automotive-type steering became common. Tractor engines varied widely with the earliest being large, heavy, horizontal one-cylinder designs (IHC Moguls and Titans prior to about 1915). Two-cylinder, opposed (Avery) and side-by-side (Hart-Parr, Advance-Rumely) engines were popular.

Four-cylinder upright engines proliferated, sometimes mounted cross-wise in the frame (J.I. Case T.M. Co., Huber), but usually parallel (IHC from about 1914 on, Wallis and many others). A few odd-balls crept in: Buffalo-Pitts used a three-cylinder engine in its 1910 Model 40-70, while the Common Sense tractor was powered by a V-8 engine.

Transmissions were equally diverse. For many years, Avery used a “shifting frame” arrangement whereby the clutch lever slid the entire engine back and forth to mesh with the forward and reverse gears.

Early IHC tractors used a friction drive, as did Heider and Rock Island a little later.

Eventually, most tractor manufacturers used a selective, sliding gear transmission, although the number of forward speeds varied.

Tractor builders struggled to find the best way of keeping their engines cool under heavy use. The first IHC tractors used their “Famous” engine that featured evaporative cooling, while Fairbanks-Morse used the same setup, with the hot water trickling over an open screen.

Big, round or square tube radiators were common, sometimes with the engine exhaust piped through the center to induce a draft of air (Avery), while others used fans (Aultman-Taylor).

Hart-Parr and Rumely Oil Pull tractors used the exhaust-induced draft system but cooled with oil instead of water, which in freezing weather prevented the daily chores of draining the radiator every night and refilling it every morning — some of those big radiators held more than 100 gallons — while the higher boiling point of oil allowed for higher cylinder temperatures and better combustion of the low grade fuels available in those days.

Rear wheel styles with cross lugs, spade lugs, and open or closed faces varied widely, as did lubrication, carburetion, and ignition, but by about 1930 tractor design had pretty much settled on two large drive wheels at the rear with two smaller steerable wheels at front — close together for row-crop work or wide apart for standard tractors.

Most tractors had disc clutches, sliding gear transmissions, tubular radiator and fan cooling and forced lubrication.

Crawlers were supported on a track on each side and steered by clutches or brakes on the tracks. Automotive-type steering was nearly universal on the wide front models and individual rear wheel brakes were common.

Standardization had finally come to the farm tractor.

The 1910-era Buffalo Pitts Triplex Tractor (with an I-3 IC-engine) was rated 35-70, per Gray. There’s really nothing wrong with an in-line three cylinder internal-combustion engine design, so seemingly criticizing that engine design in the above article is curious. After all, if you perform the calculations, I-3 engines have better reciprocating-mass balance than a similarly-sized I-4. Given the piston sizes those huge old engines had, better reciprocating-mass balance would be a benefit. That is, operating one of those big, old giant tractors with a ginormous I-4 engine would’ve produced some serious second-order vibrations. Plus, if using a sideways orientation in a tractor, there would be a packaging benefit by fitting an I-3 engine into a tractor, as compared to an I-4. Thanks for reading my comment. /Brian S. in Elma NY USA