Over the past several weeks, persistent moisture has dominated the weather pattern, leaving many farmers feeling like Charlie Brown under a perpetual storm cloud. Frequent pop-up showers, substantial rainfall, saturated soil and classic Midwestern humidity have made it difficult to find a dry window for harvesting. To make matters worse, rising temperatures have compounded the already challenging conditions.

Moisture levels and bale temperatures, both individually and collectively, significantly impact the success and safety of forage harvesting and baling. These two factors can shorten the drying window and compound the issues of wet ground conditions and high humidity. When combined with other on- and off-farm demands and tight timelines, the risk of fire and reduced forage quality increases substantially.

Understanding hay fires

According to the Farm and Ranch eXtension in Safety and Health Community of Practice, most hay fires occur within the first six weeks after baling. It’s essential for farmers to understand the conditions that lead to these fires, as well as how to recognize and reduce the associated risks.

Acknowledging and implementing safety measures provides protection for valuable resources such as forage supplies, structures, livestock, equipment, and finances from fire-related losses.

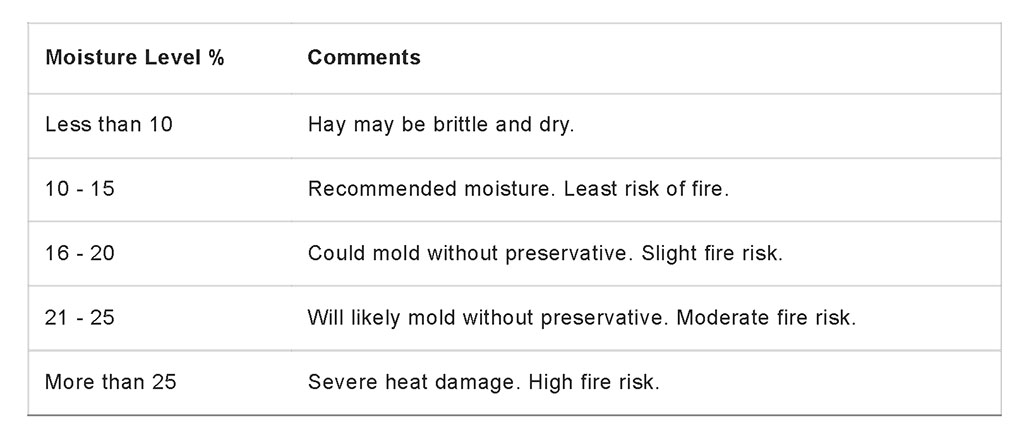

While several factors contribute to fire risk in baled and stored forages, moisture content is the most critical. Hay is more prone to combustion than straw due to its composition, higher moisture level and heat generated by microbial activity during the harvesting, baling and curing process.

After cutting, forages continue to respire releasing small amounts of heat as they dry and are baled. If the moisture content remains at or below 20%, respiration slows and eventually stops. However, baling forage with moisture levels above 20% creates ideal conditions for bacterial growth, which can lead to dangerous heat buildup during harvest and storage.

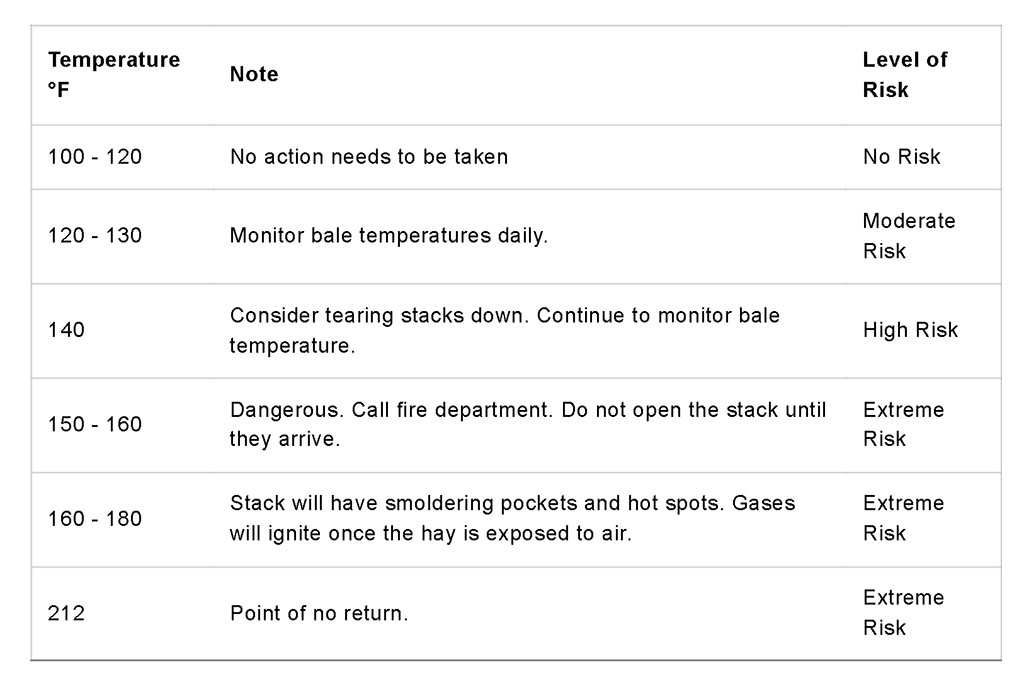

The heat generated inside a bale, referred to as “bale temperature,” results from both plant and microbial respiration. As internal temperatures rise above 140 F, the risk of fire increases significantly. Once a bale reaches approximately 150 F, the temperature typically does not decrease, and spontaneous combustion becomes more likely.

This process can take several weeks to develop.

Spontaneous combustion is driven by microbial activity and chemical reactions within the bale. Farmers should be aware that this process is often slow to develop and difficult to detect early. Larger and denser bales are especially prone to delayed signs of internal heating or burning.

Other contributing factors

Additional factors such as bale size, density and ventilation around stacked bales also influence the risk of fire. It’s important to note that some heat generation is natural even in well-cured forages with low moisture content. These bales can reach internal temperatures of up to 120 F within a few days of baling. However, they only become hazardous if the temperature fails to decline after the initial “sweat” period.

Elevated internal temperatures, even without combustion, can significantly reduce hay quality. High internal temperatures cause forage protein to bind to fiber, making them less digestible and nutritionally unavailable to livestock. At temperatures between 120 F and 130 F, an estimated 10% to 30% of available protein can be lost.

Additionally, forages baled with excessive moisture are prone to mold growth. In some cases, these molds may produce harmful toxins. Livestock consuming moldy hay may suffer from respiratory or digestive issues and in severe cases, death.

Monitoring and testing

The simplest and most effective way to monitor forage bale moisture and temperature in your operation is by using a forage moisture and temperature probe. This tool allows producers to measure conditions at multiple stages during harvesting, curing and storage. While purchasing a probe requires a small investment of time and money, the cost is minimal compared to the potential losses from a forage-related fire.

Probes are available at most agricultural supply stores and equipment dealers. Additionally, producers can contact their county Extension office (go.osu.edu/lao) to ask if the office has a probe available for borrowing.

Interested in or have concerns about your forage quality? OSU Extension invites producers to participate in a new hay testing program. The first sample is offered at a reduced rate.

Both wet and dry samples are accepted and must be submitted along with the required form and payment to your county Extension office by July 31. Obtain sampling details, costs, standard testing performed and more at: u.osu.edu/beef/2025/06/11/osu-extension-offering-hay-testing-program/.