DAYTON — As the use of drones for crop spraying moves from a promising possibility to reality, researchers at the University of Dayton are studying the movement of spray droplets after they leave drone sprayers.

Similar to conventional sprayers, the goal is for the droplets to land on target, but few guidelines exist for controlling drift with drone sprayers, said Sidaard Gunasekaran, an assistant professor of mechanical and aeronautical engineering at the University of Dayton. “The protocols are not very clear or non-existent.”

Gunasekaran is coordinating a research effort to help chemical and equipment manufacturers better understand drift potential with drone sprayers. The research is an extension of the spray drift testing he’s already doing with ground-based spraying equipment in the university’s low-speed wind tunnel.

In 2019, the U.S. EPA began accepting and reviewing sprayer data from the University of Dayton’s wind tunnel as part of the agency’s product approval process.

Drift studies

Kyle Butz, a technical advisor for Spray Analytics, has been working with Gunasekaran as an industry partner on the drift experiments. He’s hoping the drone drift studies will help head off problems with drift that could undermine confidence in drone technology.

One concern is the risk of damage from products that drift away from their intended target, he said. Drift can also result in inefficient application.

“If you do it right, you should be limiting risk at the same time as you’re increasing efficacy,” he said. “If you do it wrong, you’re losing on both sides.”

The future of drone sprayers depends on their ability to accurately target only the parts of a field that need to be sprayed, Butz said.

That would make it possible to get the same results while reducing chemical use. More research is needed, however, to see if those precise results are possible.

“Nobody’s really sure exactly what’s going on underneath a drone and that’s why there’s need for these studies,” Butz said.

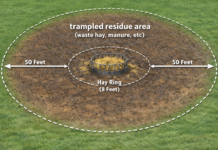

The researchers have been evaluating how the wake from drone propellers influences the size of droplets and spray patterns. One effect they’ve seen is a twisting of the plane of spray, Gunasekaran said.

A flat fan nozzle is designed to create an even sheet of spray, but the wake from a propeller twists that spray plane and knocks some of the finer droplets out of the plane.

Testing

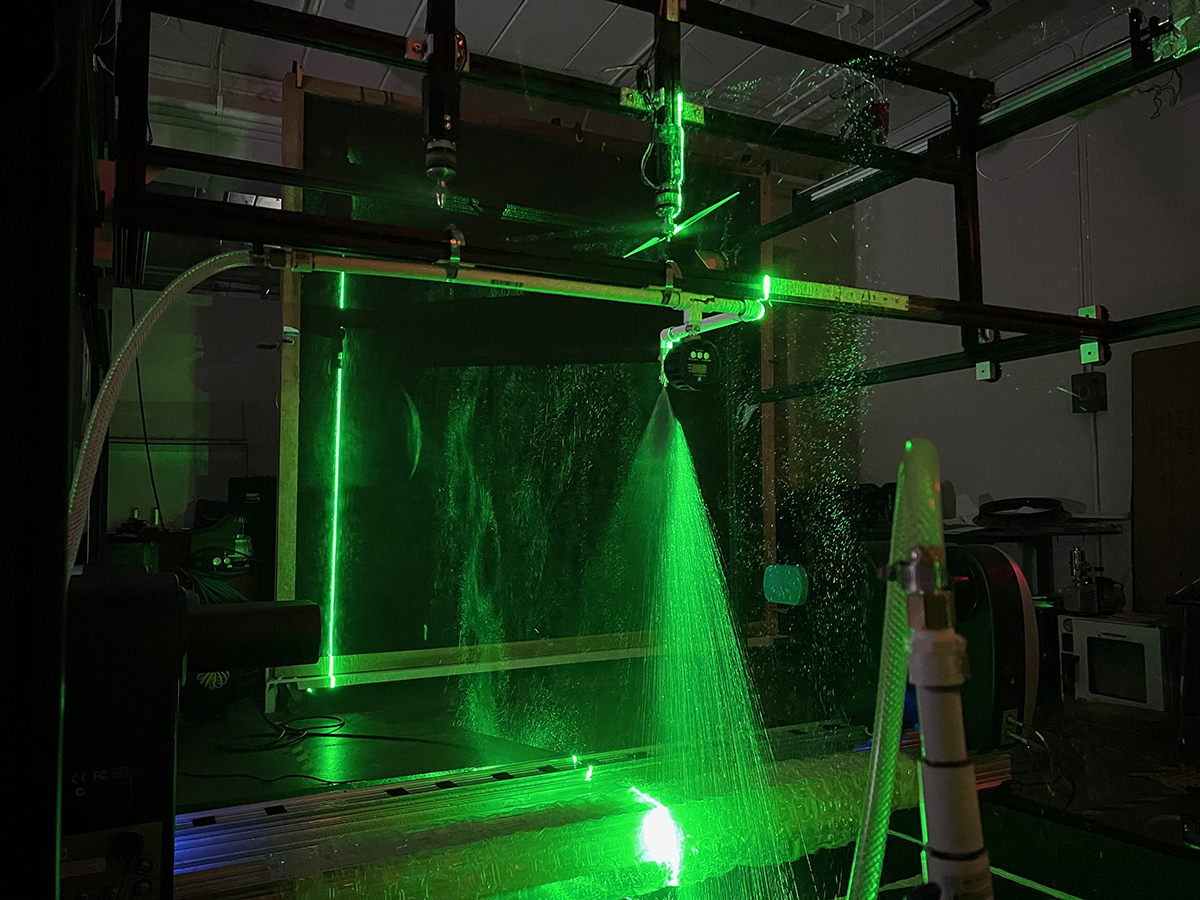

To conduct the research, Gunasekaran and Butz worked with Ian Tierney, an aerospace engineering graduate student, to build a test rig to use in the lab. The rig consists of a cube-shaped frame that holds a spray boom below drone propellers. The rig allows them to experiment with various nozzle placements, propeller configurations and propeller speeds.

The researchers used four different measuring techniques to get a full picture of how drone propellers affect spray droplets.

One technique analyzed droplet size using laser diffraction, which seemed to show that droplets from a drone sprayer are larger, and thus less likely to drift. Gunasekaran said, however, that measuring technique didn’t pick up the fine droplets knocked out of the spray plane by the propeller wake.

“That has led some researchers to believe, based on the single measurement technique alone, that spraying using drones is better because it’s making the droplet size bigger,” he said. “But, in fact, they’re not measuring the entire volume.”

In addition to the laser diffraction measurements, the researchers also analyzed the spray droplets using high speed shadowgraphs and water sensitive paper. They measured the volume of the spray collected in a gutter at the bottom of the test rig as well, Butz said.

“Between all four of those tests, we feel that we get a little bit more of a complete picture,” he said. “Any individual one of those tests probably doesn’t give us the same insight.”

More data

As they continue their drone spray studies, the researchers hope to give equipment and chemical companies, as well as government agencies, more accurate data to use in making decisions about drone spraying.

Currently, some companies are experimenting in the U.S. with the application of fungicides and crop nutritional products with drones, Butz said.

If those products drift off-target, the risk of damage is relatively low, so the industry has an opportunity to perfect drone spraying before moving on to spraying herbicides.

This approach gives the industry the chance to build confidence in the technology without negative consequences that could stifle innovation going forward, he said. “You get yourself a chance to get it right.”

Butz and Gunasekaran will be sharing their research and examining the future of drone spraying May 24 during a free seminar at the University of Dayton’s Kettering Labs. The following day, May 25, they will offer a day-long course on droplet size testing for agricultural sprays at the University of Dayton’s low-speed wind tunnel facility.

The class size for that course is limited to 12 and the cost is $995 per person.

For more information or to register for either the free seminar or the paid course, contact Butz at Kyleb@sprayanalytics.com or Gunasekaran at gunasekarans1@udayton.edu.