Fermented forages are a major component of a dairy ration and bunker silos and silage piles are often used in the production and storage of those fermented forages.

Like many situations in agriculture, it can become easy to get complacent, and overlook or forget about the inherent dangers and risks that bunker silos and silage piles can pose. The top priority when working around a bunker silo or silage pile should be safety.

As a farm manager are you aware of the potential risks and dangers of working around bunker silos and silage piles? Have you assessed those risks and taken steps to reduce safety risks?

Have you provided your employees and family members with training and knowledge of how they need to work with and manage bunker silos and silage piles?

Risks

There are two primary risks associated with bunker silos and silage piles; a person working on top of the pile falling off the pile and a person or persons on the ground near the silo or pile being buried by a silage avalanche.

The first point in silage safety is to recognize that silage avalanches are real and there is no way to predict when and where they will occur. About a year ago I was in a meeting with dairy managers and dairy farm employees and this topic of silage safety came up.

I heard a number of stories from those present about silage avalanches, falls and near tragedies. Then there are those stories that make the news; the silage avalanche that buries and kills a farm worker or family member.

If you spend any time at all investigating this topic of bunker silo safety you are likely to come across references to and material from Keith and Ruth Bolsen.

Bolsens

Keith Bolsen is professor emeritus at Kansas State University and widely recognized for his expertise in silage management. In recent years Keith and his wife Ruth have spoken out adamantly about safe management of bunker silos and silage piles.

Much of the information in this article is taken from advice and materials from the Bolsens. There are several factors that should be considered when assessing safety risks for bunker silos and silage piles.

Those factors are; height of the silage, face management and labor tasks. Height of the silage in the bunker or the pile is a primary safety factor just due to simple physics.

Objects falling from greater heights generate more force on impact than objects falling from a lower height. Most bunker silos and silage piles are packed to a density between 40 to 48 pounds per cubic foot on an as fed (moisture included) basis.

Do the math

A silage avalanche involving 2 cubic yards of silage packed at a density of 44 pounds per cubic foot weighs 2376 pounds, over a ton. That weight falling from a 20 foot tall silage face versus a 10 foot silage face represents a significant increase in force.

Silage height is also important in determining a safe working distance from the silage face.

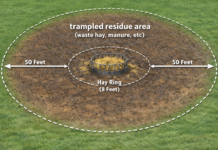

When a silage avalanche happens, the silage that falls does not just fall straight down within a few feet of the silage face. It falls down and out and upon impact spreads out, running away from the face.

For that reason, never stand closer to the silage face than 3 times its height. Face management plays an important role in silage safety.

Minimize air

The goal is minimize the penetration of air into the new silo face as silage is removed so equipment that allows a smooth face to be maintained is preferred.

Silage face shavers (or defacers) and silage rakes are designed for this purpose. Digging into the face of the silage should be minimized because that usually creates a rough, uneven face with more potential for silage avalanches.

If a front-end loader is used, do not dig into the pile from the bottom but rather remove silage from the top down, keeping the face smooth across the entire width of the bunker silo.

A smooth silage face reduces the surface area exposed to air, reduces the amount of water that may be caught and reduces, but does not eliminate, the chance of a silage avalanche.

The equipment that will be used to remove silage and manage the silage face should be matched to the bunker silo or silage pile height. Most unloading equipment can reach 12 to 14 feet above the silo or pile floor.

Piles that are taller than the equipment can reach usually have silage faces that are more uneven, and are more prone to silage avalanches. Overhangs are usually created when removing silage.

The overhangs in these silage faces are hazardous to workers removing plastic from the top of the pile. The specific job or tasks that farm labor are doing around bunker silos and silage piles should be considered when assessing safety risks.

Obviously the previous factors of silage height and face management are closely tied to this.

Pulling samples

In addition to removing silage from the face for daily feeding, other tasks may be pulling a silage sample for nutrient or dry matter analysis or pulling back plastic and/or removing tires covering the pile.

When collecting a silage sample for quality analysis, do not allow farm labor, nutritionists, or feed representatives to sample directly from the silage face.

Collect silage in a loader bucket and sample from that loader bucket after it has been moved a safe distance (at least 3 times the pile height) from the silage face.

When removing plastic or tires from the pile do not permit persons to be working where silage overhangs exist. Spoiled silage should not be hand-pitched off the top of the pile.

Remove spoiled silage with equipment operated from ground level.

All labor on the farm, including family members, should be trained on silage feed out safety and made aware of the danger of silage avalanches.

Training

Keith and Ruth Bolsen have a good DVD on silage safety that can be used for on-farm training.

For information about obtaining a free copy of the DVD, contact Keith Bolsen at keithbolsen@hotmail.com or Ruth Bolsen at ruthbolsen@hotmail.com.

The “buddy rule” can save lives. Do not allow anyone to work alone in close proximity to the silage face.

Someone should be watching from a safe distance. Since suffocation is a likely cause of death in a silage avalanche, the minutes gained by having a buddy present to call for help or rescue the injured person could mean the difference between life and death.

Finally, consider posting a warning sign: “Danger! Silage Face Might Collapse” around the perimeter of bunkers and piles. There are risks associated with silage feed out.

While those risks can’t be completely eliminated, good silage management, knowledge of risks, and implementation of safety practices may prevent a farm tragedy.